Tungsten carbide mold parts materials generally use WC and Co powders, which are mixed, pressed, and sintered to form alloy materials, which have higher strength, high corrosion resistance, and rust resistance than the original materials. It plays a vital role in the hardware and chemical machinery manufacturing industry.

The density, strength, hardness and wear resistance of tungsten steel parts should be considered.

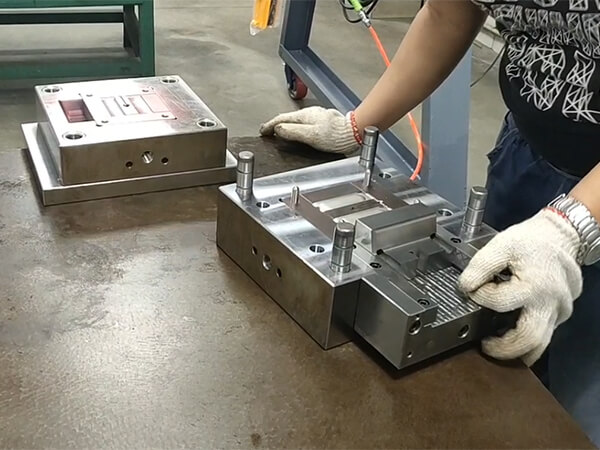

Under the continuous promotion of the development of the tungsten carbide mold parts materials industry, products made of tungsten steel materials are classified according to their shapes, including tungsten steel round bars, tungsten steel strips, tungsten steel plates, tungsten steel wafers, and ceramic sintering molds.

The processing methods for tungsten carbide mold parts materials as follow:

A. The first is the EDM machining mode through medium, slow and fast wire processing

B. The second type is welding

C. The third type is to grind the tungsten steel material through the grinding wheel

D. The fourth type is suitable for punching processing needs, using laser cutting to form and punch

Yize Mould has more than ten years of experience in processing and manufacturing tungsten carbide mold parts, which are processed according to the drawings, durable, direct sales by the factory, please call for a consultation