Save your heart & rest assured Provide one-stop solution

Yize Mould is a one-stop provider for OEM total design and processing solutions, turning your drawings into reality faster and more efficiently. Throughout the product lifecycle from concept to creation, we combine superior service with our extensive expertise in parts, molds, and injection molding to accelerate your path to success.

Why choose Yize Mould?

We help companies accelerate product development and go to market

- We have expertise in precision machining, mold design and injection molding

- We use advance technology to provide perfect products

- We provide high quality service, considerate after-sales service, and full refund if the mold is not successful.

- We specialize in precision mold design and injection molding of special plastics (including PEEK, LCP, PEI, PFA, etc.).

- We are ISO 13485, IATF 16949, ISO 14001, ISO 9001 certified.

About Us

Vision: To become a pioneer in realizing the Chinese Dream of high-end precision mold manufacturing and related products.

Specialized precision component machining, precision injection mold manufacturing, specialty plastic injection molding (PEEK, LCP, PEI, PPS, PPSU, PFA, etc.), medical-grade cleanroom injection molding, liquid silicone rubber (LSR) injection molding, PFA high-purity part mold development and injection molding, and one-stop MIM metal injection molding services.

Technology & Products

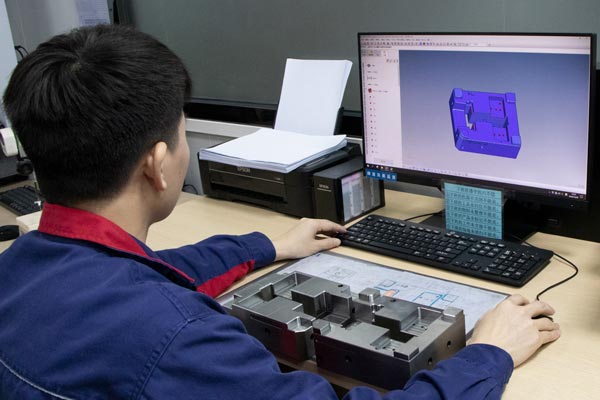

Promote the spirit of craftsmanship and pursue perfect quality. Yize Mould has accumulated over a decade of production experience, equipped with complete production facilities, achieving a tolerance of 0.002mm.

Yize constantly listens to its customers, adheres to the service concept of "customer-centricity," and is committed to becoming a practitioner of the Chinese Dream in high-end precision mould manufacturing and related products.

Yize Mould has obtained certifications such as ISO 9001, ISO 13485, and ISO 14001, and possesses a Class 10,000 cleanroom specifically for medical injection molding, which can meet the majority of medical injection molding needs.

We specialize in medical mold injection molding, complemented by liquid silicone injection molding services, focusing on precision manufacturing. We integrate “small molds” into the broader “healthcare” landscape, addressing the era's imperative.

Our PFA tube fittings are designed and processed in-house. And, we also have related patents. The products can be used in many fields such as energy, chemical, photovoltaic and so on.

Metal Injection Molding (MIM) is more suitable for complex structures and mass production, offering high material utilization, high molding efficiency, and a more competitive overall cost. CNC machining is better suited for small-batch or ultra-high-precision parts. The two methods can be flexibly combined based on project requirements.

Our History

Precision Parts

Yize Mould achieves a machining accuracy of up to 0.001mm by leveraging advanced equipment and precision machining processes. Through technologies such as CNC machining, EDM (Electrical Discharge Machining), and wire-cut electrical discharge machining, we ensure that each part meets micron-level tolerance requirements. The company specializes in the aerospace, medical, and electronics industries, providing high-precision, highly reliable components that meet stringent quality and performance demands, thereby enhancing our clients' product competitiveness.

Learn MoreMould Manufacturing

With years of experience and advanced technology, we offer our clients high-precision, high-performance mould solutions. The company employs advanced CNC machining, EDM, and other technologies to precisely control mould tolerances and quality, ensuring product reliability and stability in harsh environments. Whether for complex parts or special materials, we provide tailored precision moulds widely used in the automotive, electronics, and medical industries, helping clients improve production efficiency, reduce manufacturing costs, and ensure that every mould meets the most stringent quality standards.

Learn MorePrecision Injection Moulding

Building on our mould manufacturing capabilities, we expand production by combining advanced injection moulding technology with precision mould design to ensure that each product meets strict dimensional accuracy and superior performance. We utilize high-precision injection moulding equipment and precision moulds to control tolerances within the micron range during the moulding process, meeting the high standards for product precision and quality in the medical, electronics, and aerospace industries. Whether for complex geometric shapes or the processing of special materials, Yize Mould provides efficient and stable injection moulding solutions, helping clients stand out in a competitive market.

Learn MoreCleanroom Injection Moulding

We offer specialized medical cleanroom injection moulding services, producing high-quality, cleanroom-compliant plastic components for the medical device industry that meet GMP certification standards. We possess a Class 10,000 cleanroom and a rigorous quality control system to ensure the precise production of each injection-moulded part in a dust-free, contamination-free environment. Through high-precision injection moulding technology and strict production management, we provide the medical field with high-precision, stable injection-moulded components widely used in critical areas such as surgical instruments, diagnostic equipment, and pharmaceutical packaging, ensuring product safety and reliability and helping clients meet stringent industry standards.

Learn MorePFA Injection Moulding

We offer PFA (Perfluoroalkoxy) injection moulding services, providing customized solutions for industries requiring high purity and high corrosion resistance. PFA material exhibits excellent high-temperature resistance, chemical corrosion resistance, and electrical insulation properties, widely used in semiconductor, chemical, and electronics applications. Through advanced injection moulding technology and precision mould design, we ensure that each PFA component meets strict dimensional accuracy and high-performance requirements. Yize Mould's PFA injection moulding services provide clients with reliable, durable components that meet the demands of the most challenging working environments, ensuring product quality and safety.

Learn MoreLSR Injection Moulding

LSR offers excellent elasticity, high-temperature resistance, aging resistance, and biocompatibility, widely used in seals, gaskets, electronic encapsulation, and medical device casings. We employ advanced injection moulding equipment and precise mould design to ensure the efficient production of each LSR component within strict tolerance ranges, possessing excellent mechanical properties and durability. Yize Mould provides clients with customized LSR injection moulding solutions, ensuring products meet high-quality and high-safety requirements.

Learn MoreBiological Lab

Our medical cleanroom injection moulding services support biological laboratories, particularly in the manufacturing of biomedical equipment, laboratory apparatus, and consumables. We focus on precision injection moulding to ensure that each product meets stringent quality standards, meeting the high demands for precision, reliability, and safety in biological laboratories. Whether for sample handling, reagent storage, or components of laboratory equipment, we provide customized solutions using medical-grade plastics or other high-performance materials, ensuring product stability and durability in laboratory environments.

Learn MoreAutomated Assembly

Yize Mould possesses mature automated assembly capabilities, deeply integrating precision machining, injection moulding, and automated equipment to achieve high-consistency, high-efficiency assembly of components. Through customized automated tooling, online inspection, and process monitoring, we effectively reduce human error, improve product stability and yield, and are widely applied in the medical, electronics, and precision industrial sectors, helping clients reduce overall costs and achieve large-scale, standardized production.

Learn MoreMIM (Metal Injection Moulding)

We offer mature and reliable MIM (Metal Injection Moulding) solutions, combining the complex structural advantages of injection moulding with the high-performance characteristics of powder metallurgy to achieve high-precision, near-net-shape manufacturing of metal parts. Through key processes such as powder blending, injection moulding, debinding, and high-temperature sintering, we stably control dimensional accuracy and mechanical properties, suitable for various materials such as stainless steel and alloy steel, widely used in medical devices, electronics, automotive, and precision structural components, helping clients achieve efficient mass production and cost optimization of complex metal parts.

Learn More

Professional Team

Our company has 150 employees, including a professional team for mold design, production, and injection molding processing, capable of providing customers with the most suitable technical solutions!

One-Stop Service

Ushering in a new era of integrated precision parts, precision molds, precision injection molding, medical injection molding, and PFA tube fitting valve products!

Efficient Implementation

We have a professional production management team, introducing modern enterprise management systems, striving to impress our customers with our quality and delivery times!

Customized Production

As a professional OEM manufacturer, we support processing based on customer-provided drawings, turning your ideas on paper into reality!

About Yize mould

Become an industry leader in precision injection mold manufacturing and precision injection molding processing.

Specialized in injection mold manufacturing, injection molding of specialty plastics, medical devices & medical supplies, high-precision injection molded parts, precision parts, etc. We provide one-stop solutions.

EDM Workshop

CNC Workshop

Turned Parts Workshop

Cleanroom

Ultrasonic Cleaning Equipment

Biology Lab

MIM Workshop

Sintering Workshop

Degreasing Workshop

Our Clients

FANUC injection molding machine

Sodick EDM Machine

Hardings CNC Lathe

News

Mold manufacturing is also a process of making oneself, making the most true and beautiful oneself, and making the best contribution to customers, partners, and society.

Send a message to us