Injection molding, as a mainstream technology in the field of plastic product processing, is highly favored by the industry for its high efficiency and flexibility. However, in the actual production process, the problem of material shortage often troubles producers, affecting the integrity and quality of the products. So, what are the reasons for the shortage of injection molding? This article will conduct an in-depth analysis from four major types.

1. Raw material problem: the cornerstone of quality, which cannot be ignored

As the material basis of injection molding, the quality of raw materials is directly related to the success or failure of the product. When the raw material quality is poor, the fluidity is poor or impurities are mixed, the problem of material shortage may come quietly. Uneven particle size distribution, excessive water content or other foreign matter in the raw material will seriously weaken its fluidity, making it difficult for the plastic raw material to be fully filled in the mold cavity, resulting in material shortage.

2. Injection molding parameters: accurate setting is crucial

The setting of injection molding parameters is a key link to ensure the quality of the product. Too fast injection speed, too low injection pressure, or too short injection time and insufficient injection volume may all become the “culprit” of material shortage. Improper settings of these parameters will hinder the filling process of plastic raw materials in the mold cavity, thereby causing material shortage.

3. Mold problem: reasonable design and excellent manufacturing

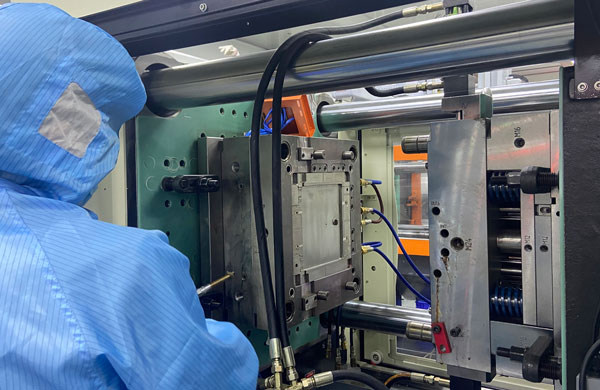

As the “mold” of injection molding, the design and manufacturing accuracy of the mold directly affects the shape and size of the product. If the mold design is unreasonable, the manufacturing accuracy is not high, or it is severely worn during use, or there are other defects, it may cause the plastic raw material to be unable to be completely filled in the mold cavity, thus causing the problem of material shortage.

4. Equipment problem: stability and reliability are the basis of production

As the core equipment of injection molding, the performance status of the injection molding machine directly affects the smooth progress of the production process. If the injection molding machine has problems such as failure and aging, or the control system is unstable and there are other hidden dangers, it may affect the filling process of the plastic raw material in the mold cavity, leading to material shortage.

In summary, the problem of material shortage in injection molding is not caused by a single factor, but the result of the combined effect of multiple factors such as raw materials, injection molding parameters, molds and equipment. In order to effectively solve the problem of material shortage, producers need to start from controlling the quality of raw materials, reasonably setting injection molding parameters, optimizing mold design and manufacturing accuracy, and regularly inspecting and maintaining equipment. Only by comprehensively applying these measures can we effectively reduce the occurrence of material shortage problems, improve product quality and production efficiency, and inject new vitality into the sustainable development of the injection molding industry.