In the process of plastic injection molding, it is a common problem that the material head remains in the mold gate. If these material heads are not removed in time, it may affect production efficiency and product quality. So, what are the methods to effectively remove these residual material heads? The following will introduce several practical methods in detail.

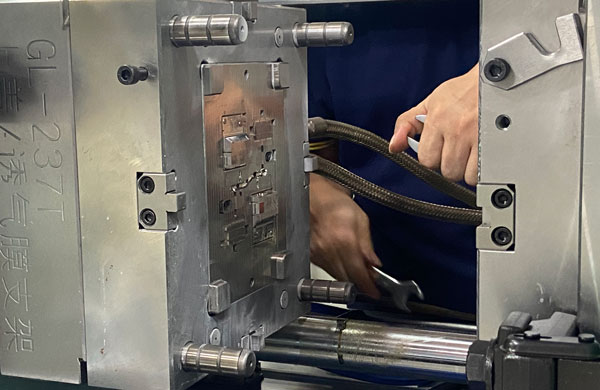

First, a common and simple method is to use a copper rod for knocking. The specific operation is to gently knock the injection gate material of the injection mold with the tip of a thick copper rod on the inside of the plastic injection mold gate. When you feel that the material head has moved slightly, use a thin copper rod to carefully remove it. In order to cope with different situations, the injection molding machine should always have several thin copper rods with a diameter smaller than the gate and a thicker copper rod.

However, it should be noted that you should never use hard tools such as screwdrivers instead of copper rods, because doing so can easily cause damage to the plastic injection mold.

Secondly, if the material head cannot be directly pierced out from the side of the sprue, we can use the heating method. The specific steps are to heat the material head to red with a heater such as an iron wire and an alcohol lamp, and then pierce the sprue material from the side of the plastic injection mold. After it is fully cooled, use pliers to pick it up. During this process, a brass plate (or cloth strip) must be placed at the lower end of the pliers to prevent damage to the injection mold when removing the sprue material.

In addition, when the above methods cannot remove the material head, we can try to use the solvent dissolution method. Apply a solvent suitable for the material (such as acetone, etc.) on the material head, wait for it to dissolve for a period of time, and then slowly remove it with a brass rod. But in this process, be sure to stay away from fire to prevent danger.

Finally, after removing the material head, don’t forget to clean the sprue hole of the plastic injection mold. You can use gas to blow it clean and spray it with a release agent to ensure the smooth progress of subsequent production.

In summary, there are many ways to remove the material head in the sprue of the plastic injection mold, and the specific method to choose depends on the actual situation. I hope the above introduction can help you and make your plastic injection molding production smoother and more efficient.