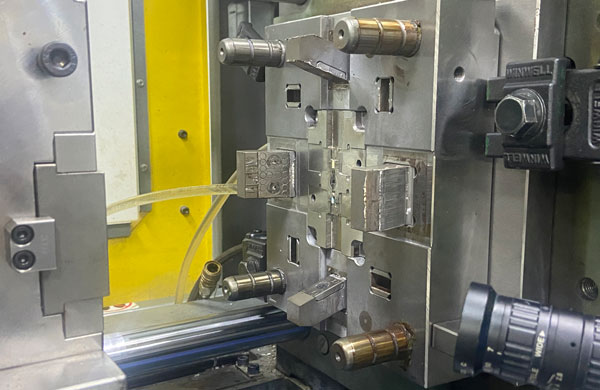

During the injection molding process of the injection mold, due to the huge effect of the injection pressure, the mold often deforms and dislocates, and then applies excessive pressure on the sliding part, resulting in the occurrence of bite phenomenon. This not only affects production efficiency, but may also damage the mold and increase maintenance costs. So, how to effectively prevent plastic mold bite? This article will elaborate on the causes of injection mold sliding, methods to prevent bite, and precautions.

1. Analysis of the causes of injection mold sliding

The main reasons for the sliding phenomenon of injection molds are as follows:

Insufficient lubrication: If the sliding part of the injection mold is not lubricated enough, the friction coefficient will increase, the sliding will not be smooth, and then bite will occur.

Insufficient rigidity: If the rigidity of the sliding part of the mold is not enough, it is easy to deform when under pressure, increasing the risk of bite.

Deformation dislocation: If the sliding part of the mold is deformed and dislocated due to improper design or manufacturing, it will directly affect its sliding performance and cause bite phenomenon.

2. Effective methods to prevent injection mold bite

In order to effectively prevent plastic mold bite, we can take the following measures:

Enhance mold rigidity: Ensure that the screws of each part of the mold are firmly fastened and improve the overall rigidity of the mold to resist deformation caused by injection pressure.

Quenching treatment: Quench the sliding part of the mold to increase its hardness and enhance its anti-bite ability.

Select suitable materials: The sliding part can be made of different steel and copper materials, and the friction characteristics between different materials can be used to effectively prevent bite.

Use lubricants: Use appropriate amounts of lubricants such as molybdenum disulfide and copper powder on the sliding part to reduce the friction coefficient and improve the smoothness of sliding.

3. Precautions in preventing bite

In the process of preventing injection mold bite, we also need to pay attention to the following points:

Lubricant selection: If the lubricant contains oil, it should be used with caution, because the oil attached to the injection molded product is prone to network cracking, affecting product quality.

Timely treatment of slight bite: Once the injection mold is found to have slight bite, it should be polished immediately and an appropriate amount of lubricant should be added to restore its sliding performance.

In summary, preventing injection mold bite requires multiple aspects, including enhancing mold rigidity, quenching treatment, selecting suitable materials, and using lubricants. At the same time, during the operation, attention should be paid to the selection of lubricants and timely treatment of slight bites. Only in this way can the normal operation of plastic molds be effectively ensured, production efficiency can be improved, and maintenance costs can be reduced.