In the field of injection mold manufacturing, grinding is a crucial step that directly affects the precision and quality of molds. So, what are the commonly used molding grinding methods in injection mold manufacturing? There are mainly two methods: form grinding wheel grinding method and fixture grinding method.

Form Grinding Wheel Grinding Method

The form grinding wheel grinding method is a distinctive grinding approach. Its core lies in using a grinding wheel dressing fixture to carefully dress the grinding wheel into a reverse profile that perfectly matches the workpiece profile. After this dressing process, the grinding wheel is used to grind the workpiece, enabling it to obtain the desired shape.

This grinding method has the significant advantages of being simple and effective and can greatly improve grinding productivity. However, it also has certain limitations. The consumption of grinding wheels is relatively high. Moreover, the surface width that can be ground in one operation using this method cannot be too large. This is because, during the grinding process, to ensure the machining accuracy, it is necessary to achieve the required precision when dressing the grinding wheel. If the grinding wheel is not properly dressed, it will directly affect the final shape and accuracy of the workpiece.

There are various types of grinding wheel dressing fixtures, including fixtures for dressing angular grinding wheels, fixtures for dressing arc-shaped grinding wheels, and template-based grinding wheel dressing fixtures. Different fixtures are suitable for dressing grinding wheels of different shapes. In practical applications, selecting the appropriate fixture according to the specific workpiece requirements and grinding wheel shape is necessary.

Fixture Grinding Method

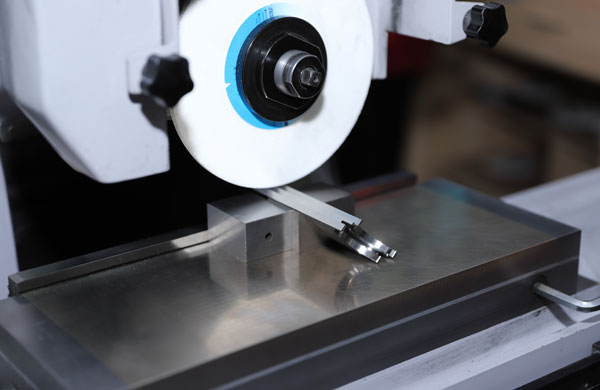

The fixture grinding method is another vital molding grinding method. It first clamps the workpiece onto a special fixture according to certain conditions. During the machining process, the position of the workpiece is fixed or continuously changed through the clever adjustment of the fixture. As the position of the workpiece is adjusted, it gradually obtains the desired shape.

The outstanding advantage of this grinding method is its extremely high machining accuracy. Through precise control of the fixture adjustment, it is even possible to make the parts meet the requirements for interchangeability. This means that the parts machined using the fixture grinding method have a high degree of consistency in size and shape and can be directly interchanged, greatly improving production efficiency and product quality.

In summary, the form grinding wheel grinding method and the fixture grinding method each have their own characteristics. The form grinding wheel grinding method has high production efficiency but high grinding wheel consumption, while the fixture grinding method has high machining accuracy. In actual production, we need to reasonably choose the grinding method according to specific workpiece requirements, production scale, and other factors to achieve the best machining results.

If you have relevant business needs in injection mold manufacturing, Dongguan Yize Mould Co., Ltd. is worth your attention. Founded in 2007, the company is headquartered in Dongguan. As an enterprise engaged in precision mold and the production of precision injection molded products for many years, the company focuses on a complete set of solutions including the automotive connectors, medical product injection molding, cleanroom injection molding, PFA custom injection molding, precision mold manufacturing, injection molding and assembly, and after – sales service. You can contact us at any time: +86 13302615729 (WeChat and Whatsapp with the same number).