In the wide range of plastic product production, injection molding technology has become an indispensable part with its high efficiency and flexibility. However, despite the widespread use of this technology, the actual production process often leads to various unqualified plastic parts due to challenges such as lack of design experience, a wide variety of plastic raw materials, complex plastic parts structure, and many factors affecting the injection molding process. These unqualified phenomena often appear on plastic parts in the form of various molding defects.

When it comes to defects in injection molded parts, the complexity of the causes is often a headache. Multiple reasons are intertwined and affect each other, making it difficult to accurately determine the root cause of the defects. But in general, these defects can be roughly attributed to three aspects: improper selection of injection molding equipment, unreasonable injection molding process design, and defects in injection mold design. So, what factors will lead to a decrease in the strength of plastic products? The following are several key reasons:

- Plastic decomposition: If plastic decomposes at high temperatures, its molecular chains will be destroyed, resulting in a significant drop in strength.

- Injection molding temperature is too low: Insufficient temperature will affect the molten state and fluidity of the plastic, thereby weakening its strength after molding.

- Poor plastic welding: If the bonding strength at the weld line does not meet the standard, it will directly affect the mechanical properties of the entire plastic product.

- Plastic is wet and not dry: If the moisture in the plastic is not completely removed, bubbles will be generated during the molding process, reducing the strength of the product.

- Miscellaneous materials mixed in the plastic: The presence of impurities will destroy the homogeneity of the plastic and weaken its overall strength.

- Improper gate position: The location and design of the gate directly affect the filling effect and stress distribution of the plastic, thereby affecting the strength of the product.

- Unreasonable product design: If there are design defects such as sharp-angle notches, it will become a stress concentration point and reduce the bearing capacity of the product.

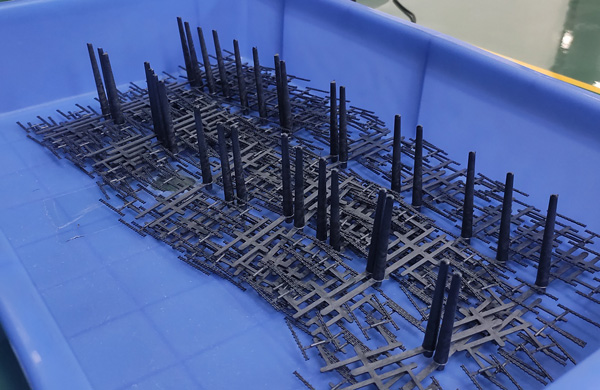

- Insufficient plastic thickness around metal inserts: If the plastic thickness around the inserts is not enough, it will be difficult to provide sufficient support and protection, affecting the overall strength of the product.

- The temperature of the plastic injection mold is too low: The mold temperature is too low, which will affect the cooling speed and crystallinity of the plastic, and thus affect its strength.

- Too many plastic recycling times: Too many recycling times will lead to a decrease in plastic performance, including a decrease in strength.

In summary, there are many reasons for the decrease in the strength of plastic products, involving plastic raw materials, molding process, mold design, and product structure. In the actual production process, these factors should be comprehensively considered and targeted measures should be taken to improve the quality and performance of plastic products.