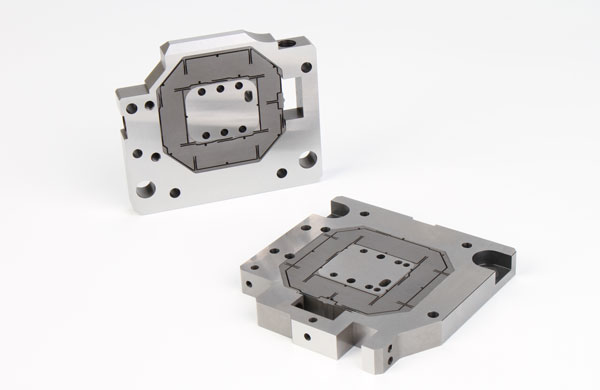

In the realm of injection molds, metal casting molds, and other mold manufacturing fields, sliders and angled sliders play pivotal roles, widely utilized in direction conversion of mold forming, lateral core pulling, and parting guidance components. When the mold is in operation, the slider or angled slider moves precisely along the guide channel under the actuation of a wedge or angled guide pillar. They either accomplish lateral forming tasks or efficiently complete lateral parting or core pulling after mold opening and before part ejection. Through these actions, sliders and angled sliders successfully achieve flexible conversion of the forming direction in injection molds, ensuring smooth demolding of plastic parts and providing robust support for the efficient operation of molds.

However, due to the diverse types of molds, the functions of sliders and angled sliders vary significantly, leading to differences in their structures, shapes, and sizes. In most cases, sliders and angled sliders are primarily manufactured modularly

. They often combine planar and cylindrical surfaces, with specific configurations varying according to the mold in use. They frequently appear on inclined planes, inclined holes, and forming surfaces with high fitting requirements, necessitating high standards for shape, positional accuracy, and fitting precision. Therefore, during daily machining processes, we must not only strictly ensure dimensional and shape accuracy but also guarantee positional accuracy relative to each other. Additionally, for sliding and forming surfaces, low surface roughness must be achieved to meet the high-precision requirements of molds.

The guiding and forming surfaces of sliders and angled sliders, subjected to frequent friction and impact, demand high wear resistance and hardness. Tool steel or alloy tool steel is commonly preferred for material selection. To ensure these materials meet the required hardness standards, specialized heat treatment processes must be arranged before finishing. After heat treatment, the performance of sliders and angled sliders will be significantly enhanced, better meeting the operational demands of molds.

If you are interested in injection molds or encounter any questions in practical applications, feel free to click on the online customer service on our website for consultation or directly call: 13302615729. Dongguan Yize Mold, with its professional team and extensive experience, will provide you with comprehensive and attentive service, helping you avoid detours on the path of mold manufacturing and achieve more desirable results.