In the process of injection mold processing, many factors such as material selection, mold process design and factory management mode have a crucial impact on processing costs. In order to cope with different application requirements, such as high hardness, high wear resistance or high toughness mold steel selection, we must carefully plan in production engineering to effectively control the processing cost of injection molds. Below, I will elaborate on three aspects.

1. Lean steel selection

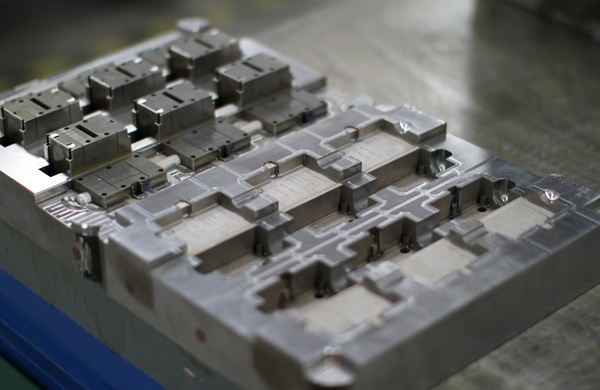

In the manufacture of injection molds, the selection of steel is crucial. Some applications require high hardness and high wear resistance mold steel to enhance the durability of the parting line; while other applications pay more attention to the toughness of mold steel to resist mechanical fatigue. However, high hardness and wear resistance steel tends to be more brittle, while tougher steel may have reduced performance in steel-to-steel abrasion, glass fiber or mineral-filled resin abrasion. Therefore, mold makers need to carefully select the right steel according to specific needs. In addition, stainless steel is a worthy choice for molding resins that are corrosive to most other steels. Before product production, rationally designing the injection mold and selecting the appropriate steel are the basis for reducing costs. Excellent mold design can increase the yield rate and reduce waste, thereby effectively reducing production costs.

2. Rationalization of processing technology

The choice of processing technology is also crucial to the cost control of injection molds. The same product, using different production and processing technologies, will require different raw material quality and quantity. Therefore, on the premise of meeting product quality requirements, we should actively explore and improve processing technology to reduce production costs. By optimizing the processing flow, improving processing efficiency, and reducing material waste, we can achieve effective control of processing costs.

3. Scientific management model

In the processing of injection molds, a scientific and reasonable management model is also indispensable. We should strengthen the awareness of cost accounting and strengthen management in various links such as production, supply, sales and finance. Specifically, the raw materials, auxiliary materials, fuel, power, wages, manufacturing costs, administrative expenses and other expenses in the production cost should be refined into the unit product cost to achieve refined management. At the same time, wasteful behavior should be strictly prohibited to ensure that every penny is spent on the blade. By reducing unnecessary waste in each link, we can reasonably store and use materials, reduce costs and improve efficiency. This can not only meet the reasonable needs of production, but also reduce the occupation and waste of funds.

In summary, through lean steel selection, rational processing technology and scientific management mode, we can effectively control the processing cost of injection molds and improve the competitiveness of enterprises.